ニュース

NEWS

-

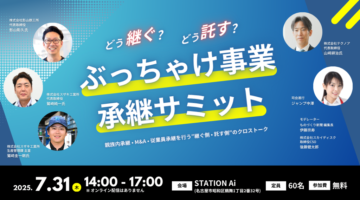

【7/31(木)名古屋開催】スカイディスクと ものづくり新聞が「どう継ぐ?どう託す?ぶっちゃけ事業承継サミット ―親族内承継・M&A・従業員承継を行う”継ぐ側・託す側”のクロストーク―」 を開催します

-

【7/11(金)開催】スカイディスクが浜松市主催の「浜松市内ICT企業5社が登壇!製造業のためのDXおたすけサービス紹介セミナー!」に登壇します

-

スカイディスクが、広島県が行うAI技術で地域の課題解決を目指す『ひろしまAIサンドボックス』に採択

-

株式会社スカイディスク、大阪府と事業連携協定を締結 ~中小企業のDX推進を支援する「大阪府DX推進パートナーズ」に参画~

-

【5/14(水)開催】スカイディスクが 小牧市・こまき新産業振興センター主催の「こまきDXテックミートアップ」に登壇します

-

AI搭載の生産計画DXサービス「最適ワークス」が、2025年度のIT導入補助金対象ツールに認定

-

ゴールデンウィーク休業のお知らせ(2025年度)

-

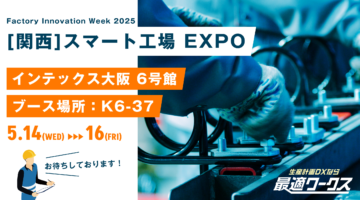

最適ワークスがFactory Innovation Week 2025『第1回 スマート工場 EXPO(関西)』に出展します

-

AI搭載の生産計画DXサービス「最適ワークス」を提供するスカイディスクが浜松いわた信用金庫とビジネスマッチング契約を締結

-

スカイディスクが常陽銀行とコンサルティング×最適ワークスの新たなビジネス創出検討を開始

-

AI搭載の生産計画DXサービス「最適ワークス」を提供するスカイディスクがホンダトレーディングと協業を開始

-

【3/19(水)開催】スカイディスクが愛知県主催の「AICHI INNOVATION CHALLENGE」に参加しました

-

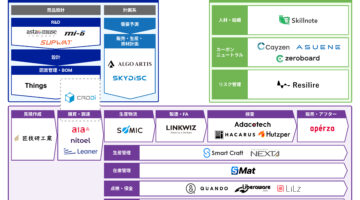

スカイディスクが『製造DXスタートアップ カオスマップ』に掲載されました

当社およびサービスに関するお問い合わせ・資料請求は、

下記よりお気軽にご連絡ください。

GET IN TOUCH

GET IN TOUCH

GET IN TOUCH

GET IN TOUCH